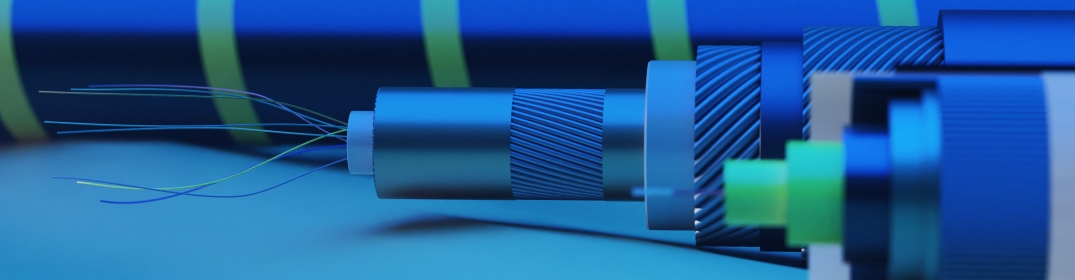

Cable/Umbilical Structural and Installation Analysis

Overview

Owing to the differing conditions, and hence requirements, of each subsea system nearly every cable and umbilical will have a unique design. In addition, as there is often no redundancy built into the vital communication link the umbilical becomes a very high cost/ risk product. Therefore minimising the risks to the cable or umbilical is of great importance.

Invariably, once installed and trenched, cables and umbilicals operate under static conditions. They are therefore designed primarily for a static application. During manufacture and installation though, an cable or umbilical will experience dynamic loading.

High cost prohibits the manufacture of fully dynamic cables and umbilicals for all applications. It is therefore essential to know the limits, of each component under loading. A full understanding of the loading conditions the cable or umbilical will experience during manufacture, installation and operation is also required to enable risk minimisation.

Installation Operations

Simultaneous lay and trench operations can subject an umbilical or cable to the highest loads of its service life. The greatest potential for damage will occur during unexpected vessel motions because of adverse weather conditions, and especially when laying needs to be stopped due to an installation equipment failure.

This can lead to a cable or umbilical being kept suspended from the lay vessel for substantial periods. The vessel motions subject the cable or umbilical, in its catenary configuration, to continuous bending. This occurs mostly at the seabed touchdown point and at the departure point from the lay chute.

Careful assessment of the lay operation, throughout its duration, is needed to ensure none of the structural limits are exceeded. As the vessel motions are the main risk to the cable or umbilical, by relating these to the resulting forces experienced, a method of assessing the lay operation conditions can be established.

Umbilical/Cable Structural Analysis

The first stage is to carry out a structural analysis of the cable or umbilical to be installed. This involves using advanced structural analytical models to predict the axial, torsional and flexural mechanical behaviour of the whole structure.

Minimum bend radius values can be obtained for each component of the cable or umbilical, which will then give the limiting bend radius as a whole.

Vessel Motion Analysis

The second stage involves analysing the motions of the lay vessel.

Hydrostatic and hydrodynamic analyses are carried out using pressure integration, and three dimensional diffraction methods respectively. The latter give the required information about the vessel accelerations due to wave induced motion.

Cable/Umbilical Dynamic Analysis

The third stage consists of taking the results from the previous two stages, and using them to perform hydrostatic and hydrodynamic analyses on the cable or umbilical. Firstly, the catenary profile is calculated, then the umbilical is loaded with the wave forces, and vessel induced excitations, which are to be expected during the lay operation.

This stage is carried out using a finite element method. The results enable lay operational limits to be made. This can be done by relating the vessel heave accelerations, to the respective induced maximum bending moment within the cable or umbilical, taking account of the values produced in the structural analysis together with appropriate safety factors.

Installation Monitoring

The final stage is to monitor the actual installation of the cable or umbilical from the lay vessel. By measuring the vessel accelerations, an instant value of maximum bending moment can be obtained during the lay out. This data can be recorded to form short and long-term time histories of the operation, with respect to the forces induced by the vessel into the cable or umbilical. At any time during the operation, the data can be examined giving an insight into the trends of the vessel motions, and hence the cable or umbilical loading conditions due to the weather conditions.

BPP has the in-house capabilities to carry out cable and umbilical structural and installation analyses for clients.

Related Sectors

- Thermal Assessments

- Subsea Cable Engineering

- Subsea Cable Protection

- Electro-magnetic Field Effects

- Cable Condition Investigation

- Telecommunication Cable Services

- Cable Fatigue Life

- Dynamic Cable Ratings

- Cable and Materials Testing

- Cable Manufacturing Support

- ECG™ Holistic Cable Monitoring System

- AI & Machine Learning for Subsea Cable Data